special purpose machinery

INDIVIDUAL SOLUTIONS IN ALL AREAS

As a flexible partner, we offer you customised solutions for your individual tasks in the field of special machine construction. As a think tank, thanks to our many years of experience, we develop creative working tools in a wide range of subject areas and build machines, tools as well as aids adapted to your needs. Whether it is a one-off or a small series, we will be happy to advise you.

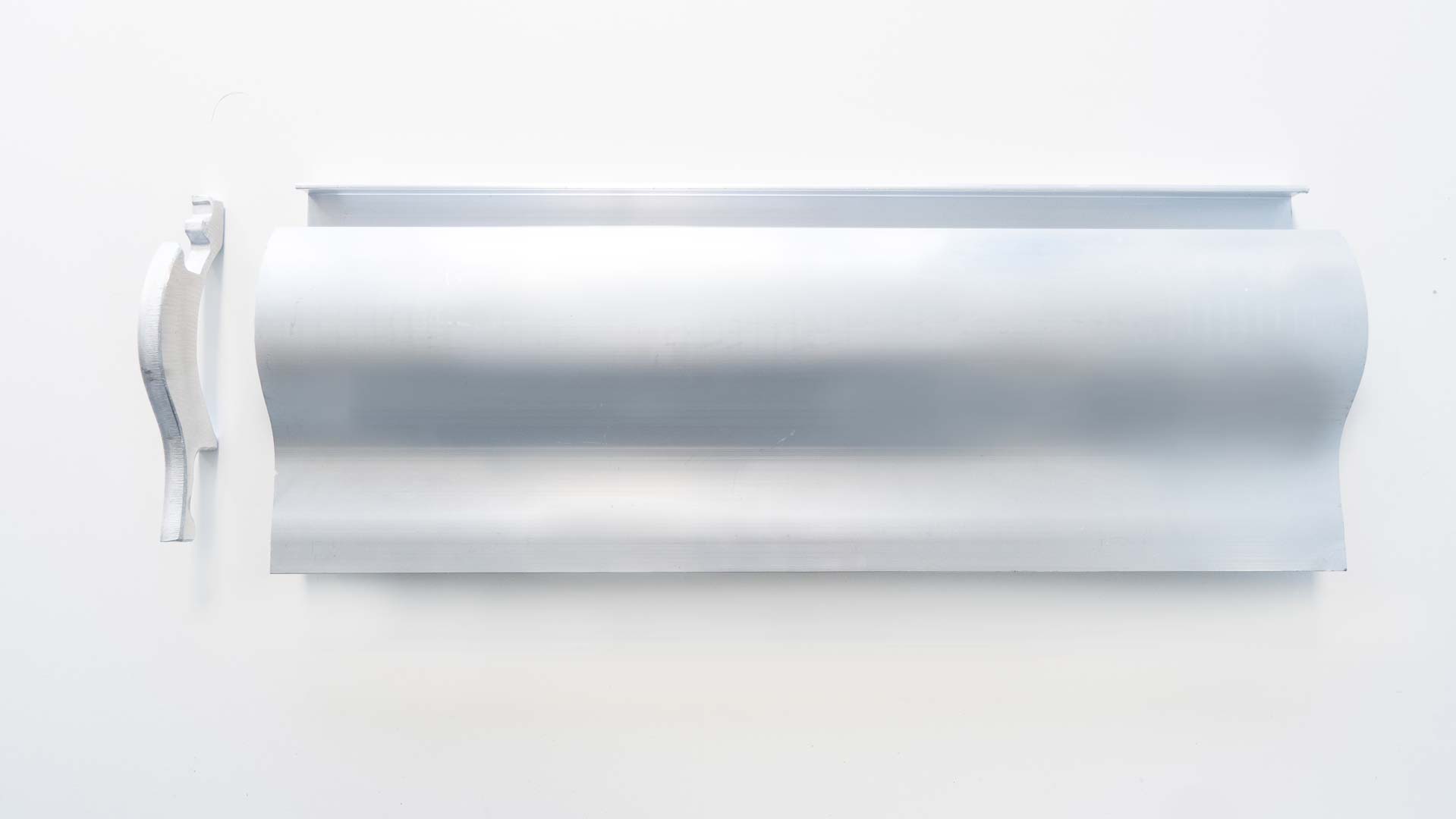

VACUUM ROLL TURNER

The diverse use of vacuum rolls in the paper and film industry has long been established. With the vacuum roll rotator developed by paXos, the complete cleaning of the vacuum drum can be carried out in a simple way. The core of the invention is to set the vacuum roll into a rotating motion. It can be mounted at a height of up to 3 metres. By means of a pneumatic motor, the vacuum drum to be cleaned is gently set in motion via a long-lasting, wide tyre, so that a long service life can be assured.

Due to the ingenious special design, the force exerted by the vacuum roller turn is always directed vertically downwards. No tilting moments are exerted on the construction. By supporting it on a stationary vacuum drum, the rotation moment is compensated for, which is triggered via the drive wheel on the vacuum drum to be rotated.

Specifications

- Moving round objects up to a height of 3 m in a rotating motion

- Drive with a currentless pneumatic motor in a safety-critical environment

- Durable and gentle on materials due to the use of robust components

- Flexible positioning due to versatile adjustment options and heavy-duty castors

- Securing on all standard work platforms and scissor jacks by means of anti-tilt device

- Easy handling during commissioning

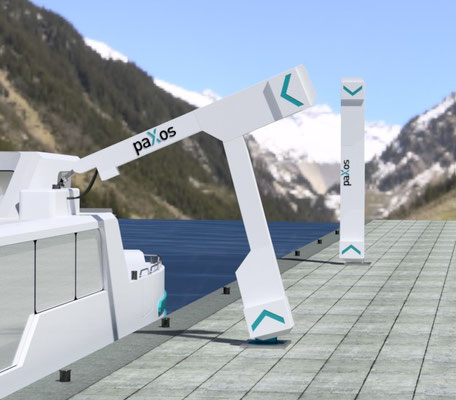

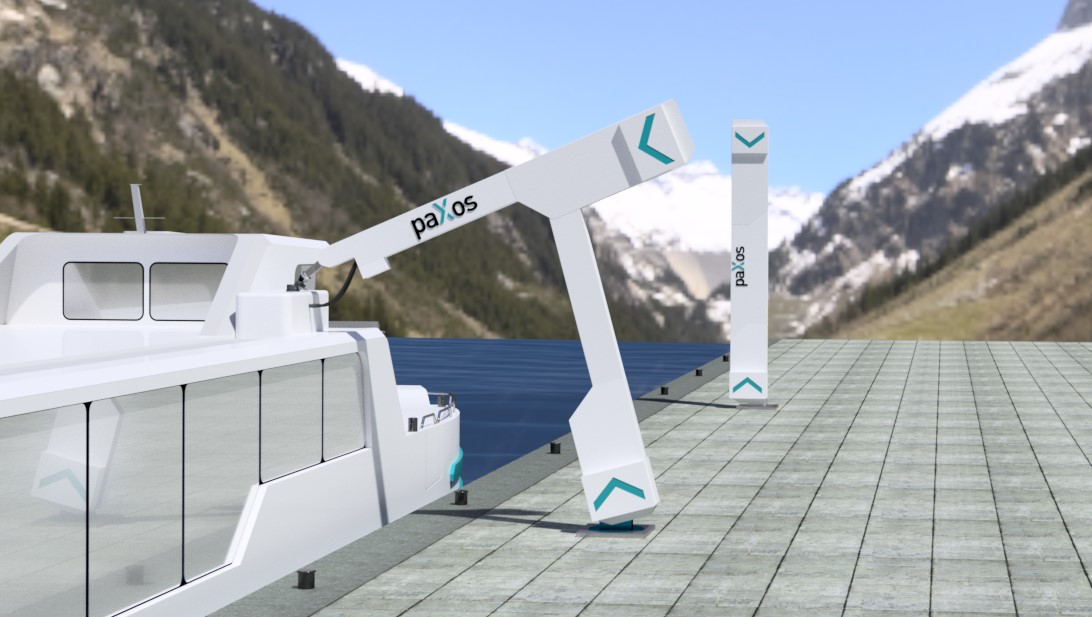

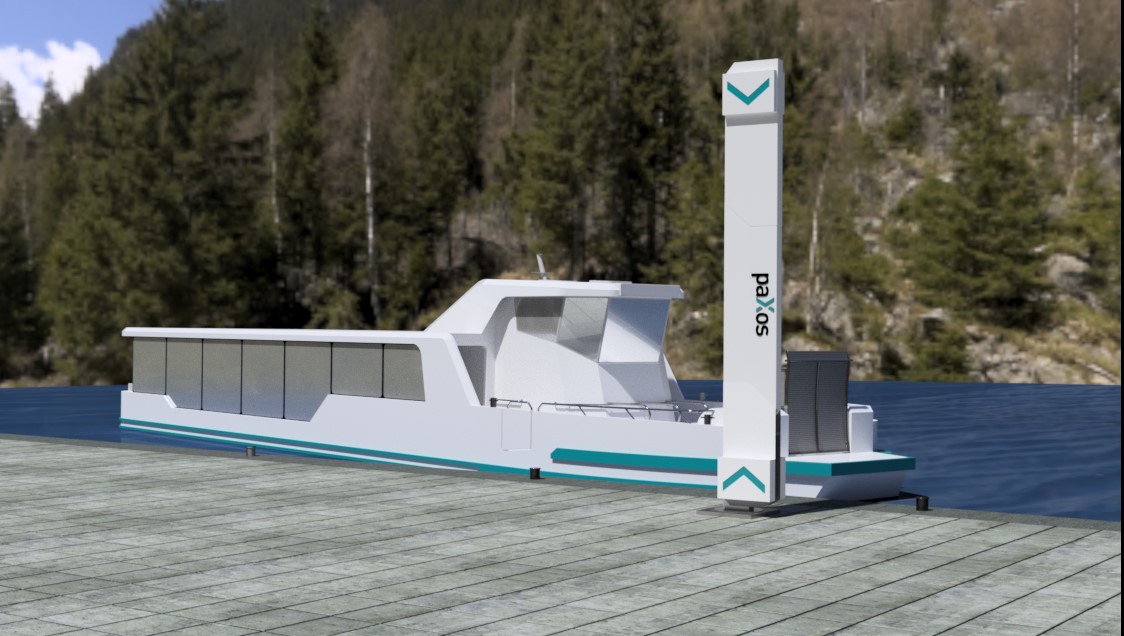

Cable bridge

The cable bridge creates a secure and at the same time flexible connection between a charging station and a vehicle that allows relative movements. Especially in the maritime sector, movements occur in all six degrees of freedom between the quay and the ship, which can be irregular. Other areas of application are in agriculture or aviation.

When electrifying ships, it is essential for a reliable charging connection to secure the charging interface mechanically on the one hand and to relieve the charging cable, plug and socket on the other. A towing eye is used to connect the cable bridge to the vehicle. Then the charging cable is connected to the charging socket on the vehicle. The video shows how flexible the cable bridge is.

Specifications

- Storage for charging cable and plug inside

- Small footprint when folded up

- Three-part construction with towing eyelet for extensive flexibility

- Low forces required to move

- Swing arms above a height of 2.3 m

- Application potential in areas with special weather conditions

- Easy maintenance access through maintenance flap

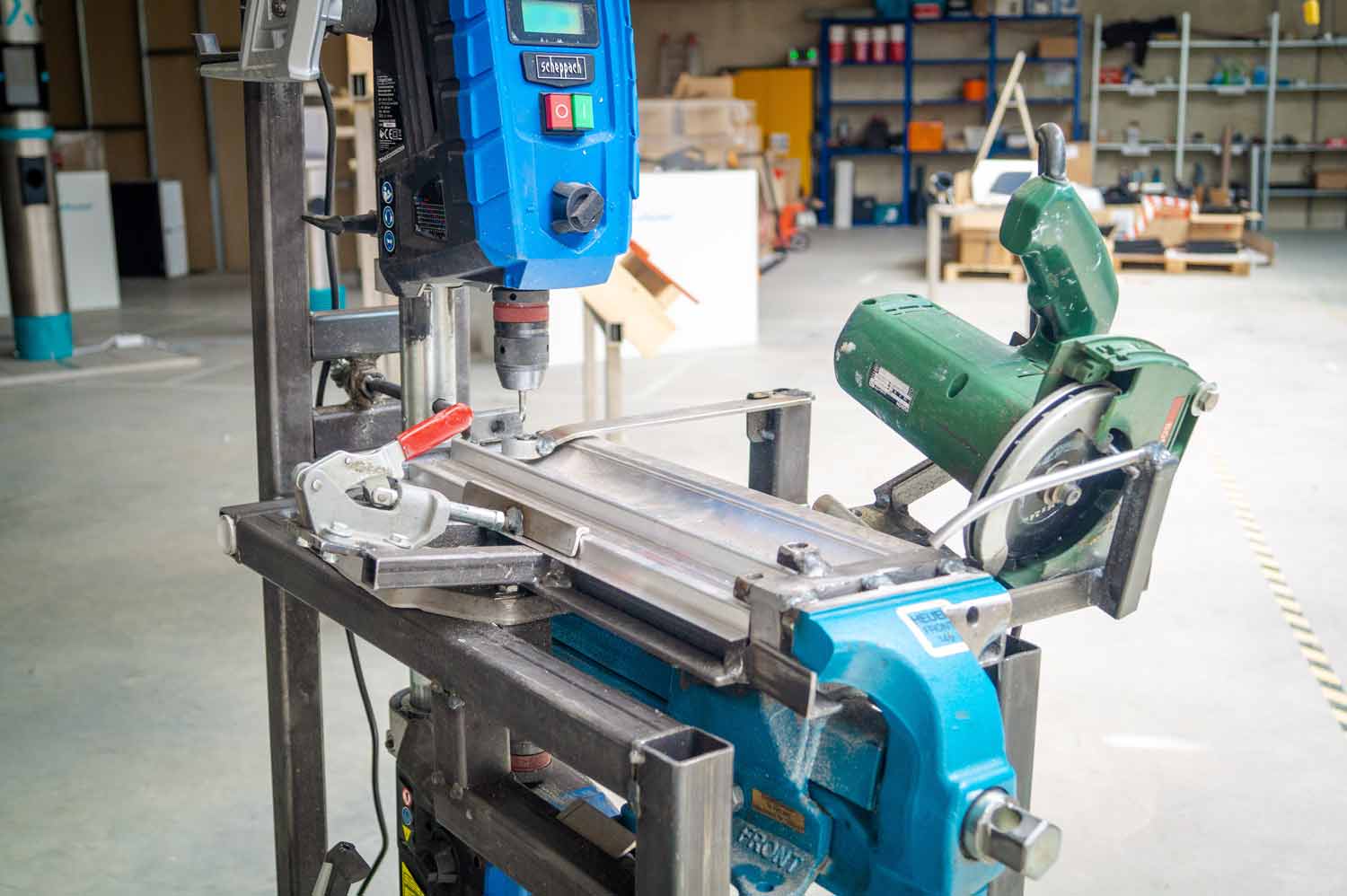

Profile Processing Machine

An outsourced production of the corrugated profile suitable for the Mild-Hybrid solar roof tile could not be economically justified. The high estimated production costs led to the development of an in-house, cost-effective machine that covers all work steps.

With the so-called corrugating machine, it is possible to produce corrugated profiles from prototypes to small series. Due to the well thought-out arrangement of the tools, it is possible to process all work steps in one machine. In this way, the following work steps are carried out directly. The in-house construction is stable and easy to maintain. The cycle time of the semi-manual production is only 180 s, so that 20 shaft profiles can be produced in one hour.

Specifications

- Stable frame anchored in the ground

- Two power drills with drilling or milling head

- Handheld circular saw on tilting plate

- Modified vice with boreholes

- Clamping design with toggle clamps

- Operation with battery-operated impact wrench and battery-powered drill screwdriver

The machine shown is a one-off production. In the larger production framework of special machines, customer-specific options are proposed for tool arrangement, stability and ease of maintenance, and sensible decisions are made.

WORK FLOW

- Loading and clamping the workpiece

- Drilling of the holes and slotted holes by using integrated tools

- Insert the wave profile cap and press it with a vice

- Machining the shaft front with the circular handsaw

- Loosen and remove workpiece

KONTAKT

INFORMATIONEN | BERATUNG | AUSKUNFT

Tel: +49 2173 200 43 30

Karl-Benz-Str. 9

40764 Langenfeld (Rhld.)

Deutschland / Germany