Electromobility

HIGH PERFORMANCE CHARGING INFRASTRUCTURE

For us, electromobility is the future. Used sustainably, produced in a resource-friendly and resource-saving way, and efficient in operation. We are driving the new age forward with our developments. With creativity, pragmatism and know-how from the automotive sector, we are currently developing vehicle-side solutions for a stable charging infrastructure with charging stations, plugs and cables.

Overview of electromobility Innovations

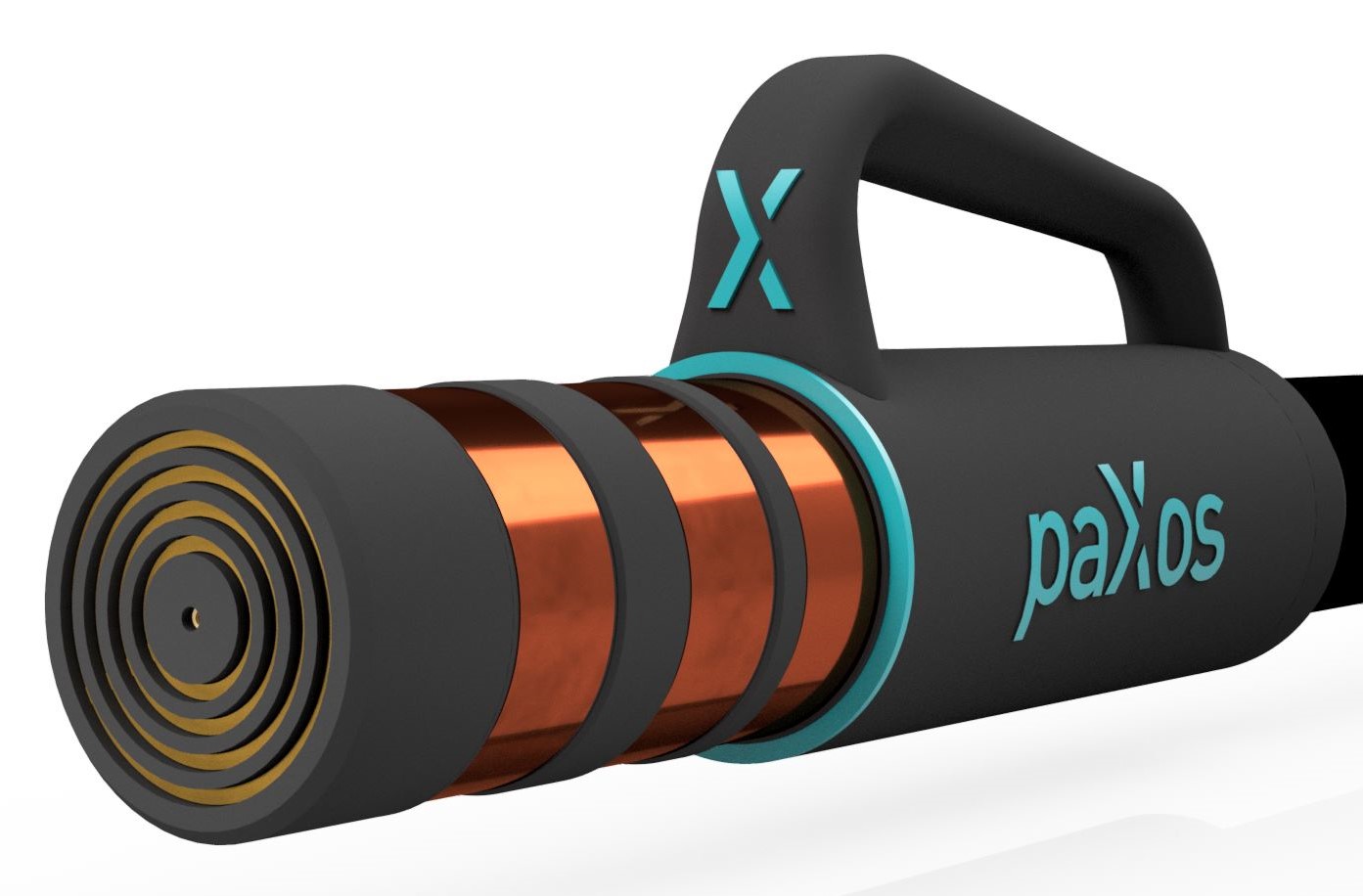

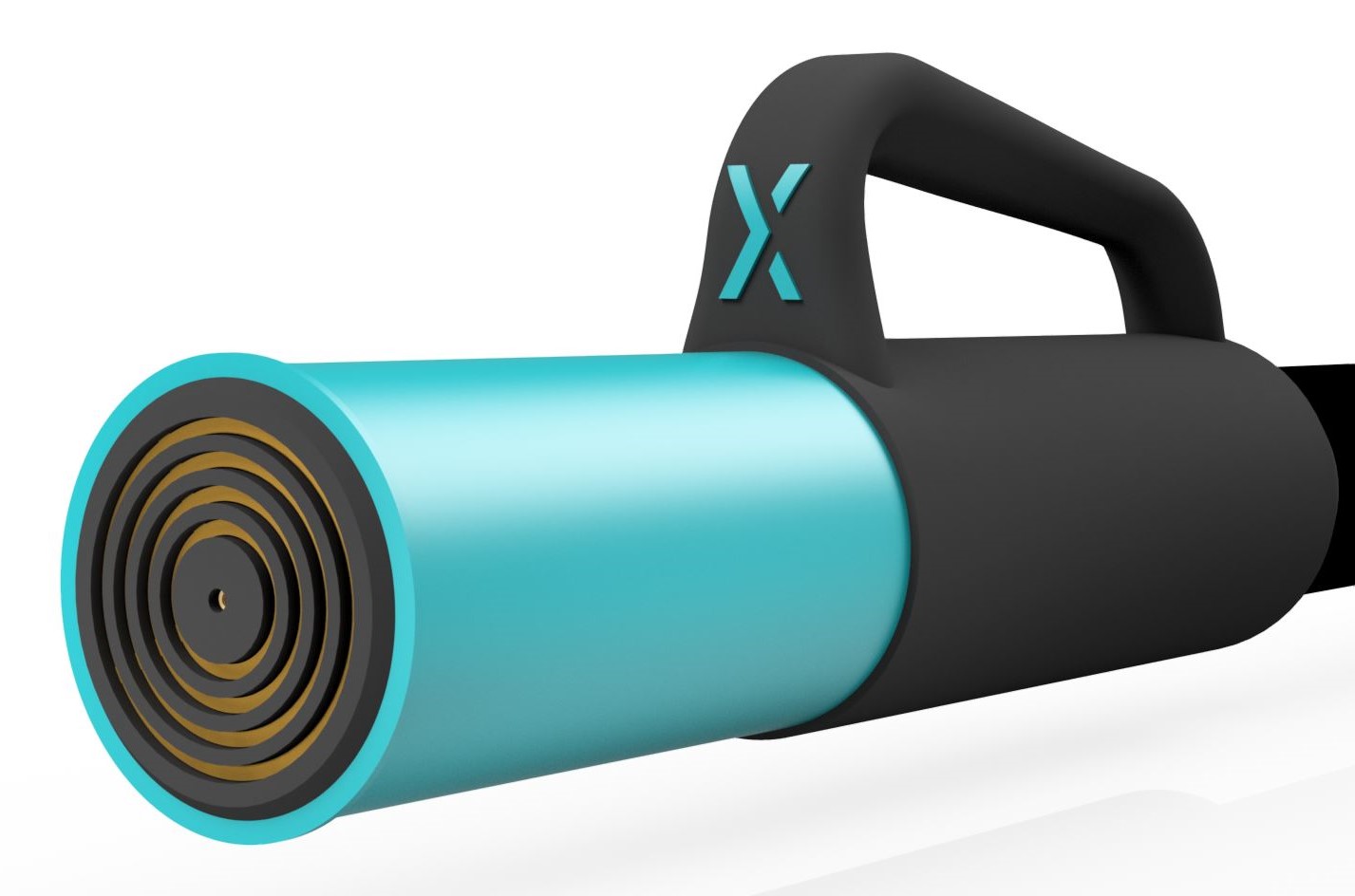

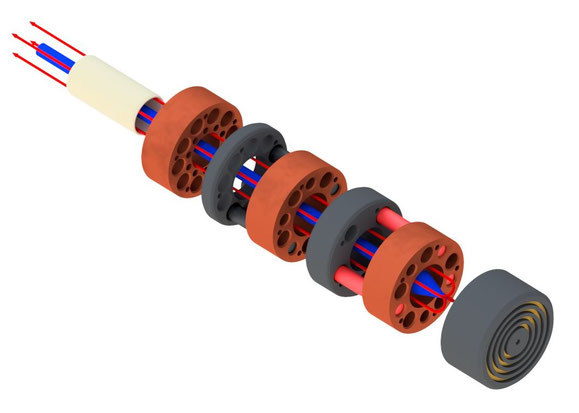

Charging Plug Cool-Load Megawatt (3 - 12 MW)

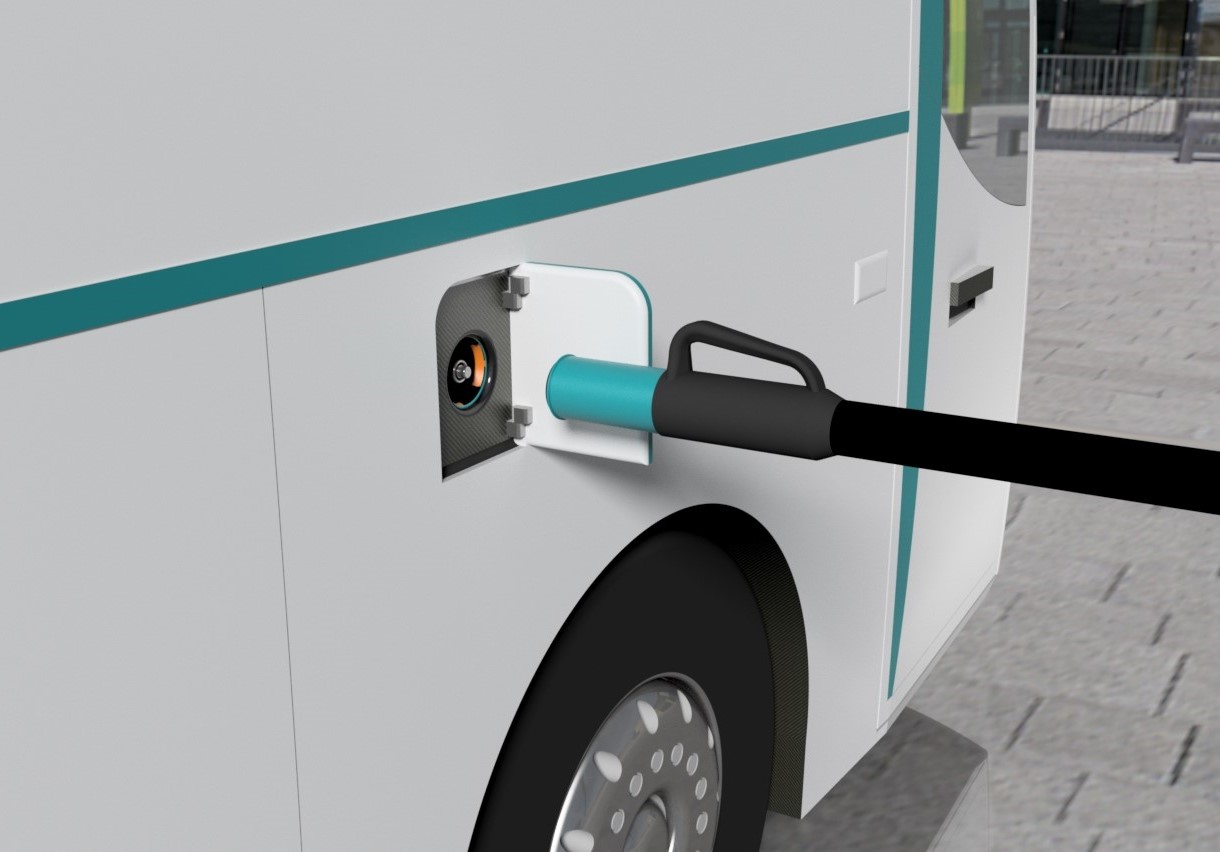

The charging plug Cool-Load Megawatt impresses with its high charging power and stylish appearance. Due to the integrated active cooling, the large contact surfaces and the automatic control of the contact closure, charging powers of over 3000 kW are possible. By scaling the plug diameter, these can even be increased to more than 12 MW. This means that in the future a vehicle can be charged comfortably and in significantly less time than is currently possible.

Especially in the commercial vehicle sector and for long distances, battery-electric vehicles are currently not profitable for companies. With the Cool-Load Megawatt, this can be changed sustainably.

With the charging plug Cool-Load Megawatt, a large contact area is achieved for energy transfer. Thanks to the integrated liquid cooling, losses in the cables and at the contacts are significantly reduced. As a result, higher currents can flow, enabling faster charging. The multiple stranded individual cables and cores in the charging cable result in a high degree of flexibility that is in no way inferior to classic fuel hoses.

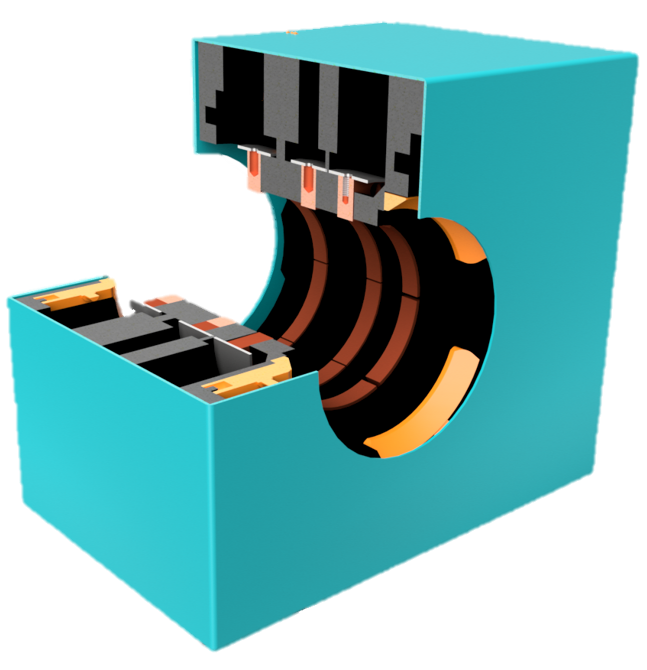

Via an ingenious mechanism, the contact rings of the charging socket are tightened after the charging plug has been inserted without force, thus generating a high contact pressure. The charging process starts automatically after verification.

special features

- High charging power (3 - 12 MW)

- Scalability of design allows even charging power up to 40 MW

- Very high efficiency (99.74% at 5 MW)

- Comparable handling and flexibility as current liquid fuel systems

- Easy, force-free & orientation-free plugging in

- High safety due to covering of poles and automatic plugging & locking process

- Active, large-area cooling of all electrical components

- Coolant transfer to the vehicle possible

- Long service life (min. 100,000 charging cycles)

ADVANTAGES

- Size of the contact surfaces when plugged in Compared to classic fast charging plugs, the Cool-Load Megawatt has a contact surface that is more than 8 times larger.

- Increased contact pressure The higher contact pressure is realized in the socket via a toggle clamp. Subsequent clamping compensates for tolerances and ensures a large contact area.

- Full-surface contact connection In contrast to classic charging connections, current is not transmitted via pins but via a ring structure. The tap and thus the utilization is increased and the contact area massively increased.

- Full-surface grinding of the contact surfaces With classic charging plugs, grinding of the contacts takes place linearly during plugging in and unplugging. In the long term, this leads to erosion of the conductive material at the contact points - the charging performance decreases. Our plug is inserted without force and ground evenly, so that a significantly longer service life can be achieved than with a conventional plug.

- Active cooling The cables and contact rings are surrounded and cooled over a large area by a non-conductive fluid, which also cools the charging socket. In addition, the cooling fluid can be transferred to the vehicle via a controlled, coaxial ball valve.

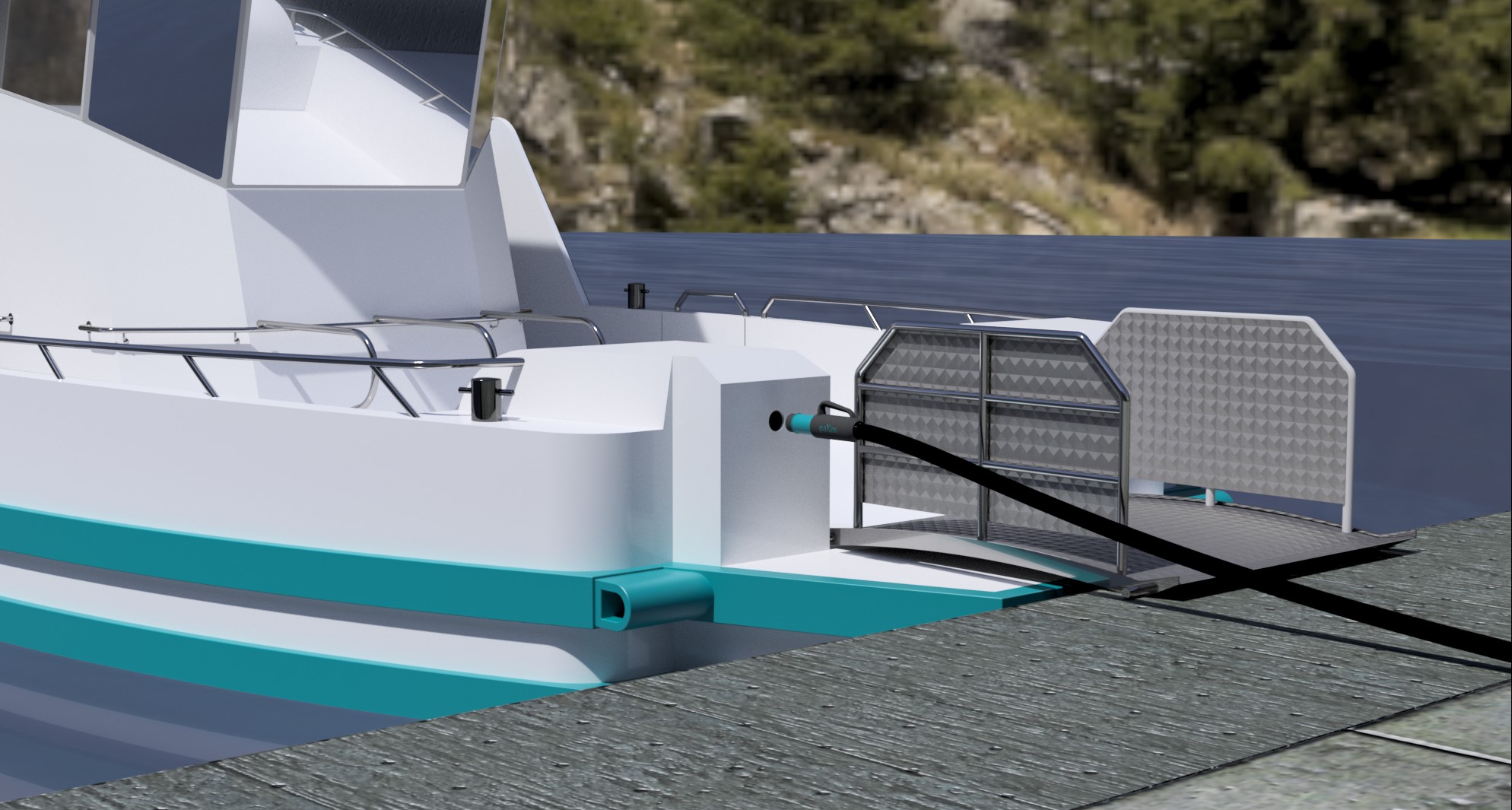

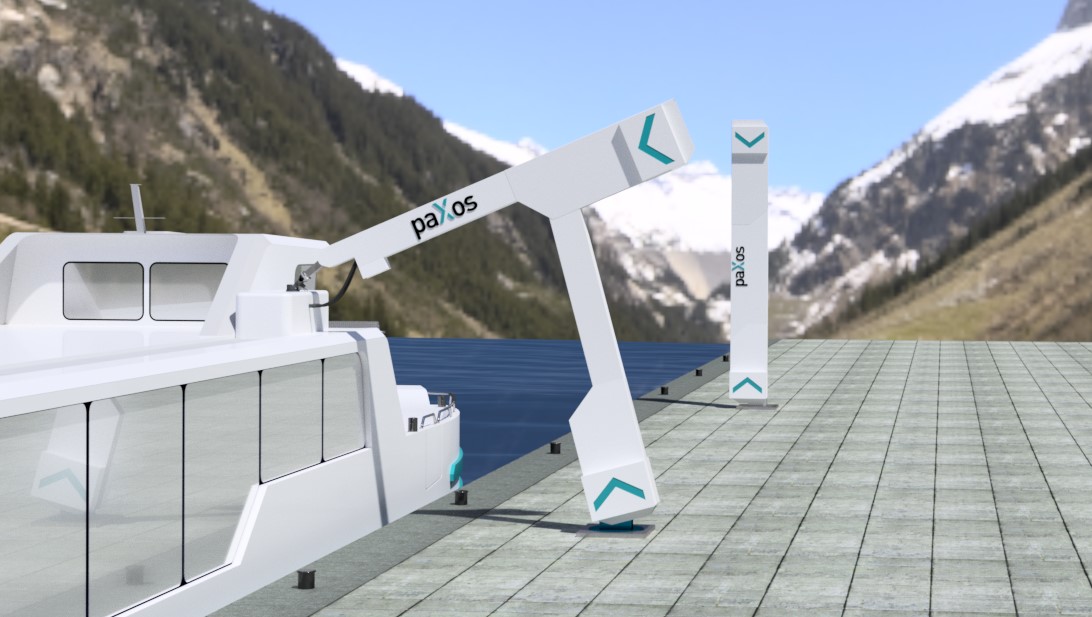

APPLICATION IN THE MARINE & AVIATION SECTOR

In addition to the vehicle sector, the maritime sector and aviation are also becoming increasingly electrified. The charging plug Cool-Load Megawatt is also the optimum solution for these areas of application, as it meets the increased requirements for contact reliability due to strong waves or storms as well as increased air pollution due to salts or dust. By creating a slight overpressure under the protective tube, but also when coupled to the charging pole and with the socket, the penetration of salty air into the plug connection, for example, is prevented.

For the charging process in the maritime area, the use of our cable bridge is also ideal. Between quay and ship, movements occur in all six degrees of freedom, which can be irregular. With the cable bridge, a safe and at the same time flexible connection between a charging station and a ship is established, which allows relative movements.

tEChnical INFORMaTION

| Parameter | CL 3 - 12 MW |

|---|---|

| Power | 3 - 12 MW (dc 100 %) |

| Nominal Voltage | 1,500 V |

| Nominal Current |

2,000 - 8,000 A |

| Contact Area | 5,300 mm² |

| Surface Pressure | > 100 N with mechanical connection system |

| Insertion Force | ~ 0 N |

| Handling | Disoriented contacting |

| Cooling | Direct contact cooling |

Research Project IDEAL

In the IDEAL project (Innovative DC Technology for Sustainable Integration of Modern Charging Infrastructure for Electromobility), new types of DC-based charging solutions for electromobility are being researched. The grid connection will no longer be via alternating current, but via direct current, and the feed-in points for the local direct current grid will be distributed at grid interconnection points, such as substations or local grid station

As part of the project, a high-power charging pole and an urban charging pole with medium power will be developed in addition to the high-power charging plug from paXos. Testing of the components will be carried out in a hardware-in-the-loop environment, creating both a test environment and market-ready products.

The IDEAL project is a collaborative research project with the following research and project partners:

- elexon GmbH

- Institute for Power Generation and Storage Systems (PGS), RWTH Aachen University

- Chair of Controlling, RWTH Aachen University

- Chair of Energy System Economics, RWTH Aachen University

- Siemens AG Technology Research in Energy and Electronics

The project is funded by the German Federal Ministry of Economics and Climate Protection (BMWK).

Charging Cable

To match the charging plug Cool-Load Megawatt, we are currently developing a charging cable that is actively cooled and enables high charging power. Individual, stranded cables lead to greater flexibility and create the feeling of holding a classic fuel nozzle in your hands.

SPECIAL FEATURES

- High flexibility due to stranding of the power lines around the coolant supply line

- Higher current carrying capacity possible due to optimized cooling

- Optimized cooling in the charging cable due to direct, large-area flow of the cooling fluid around the stranded individual cables

- Low temperature of the outer sheath due to heat reflecting surface on the inside

Charging Stations

small charging station

- Clean, functional design

- Large touchscreen with options for individual operating systems

- Use with classic charging plugs or the paXos Cool-Load Megawatt

- Safe placement of all essential elements in the charging station

- Robust against parking bumps due to patented predetermined bending point

SMALL CHARGING STATION (EXTENDABLE)

- Inconspicuous integration in city centers due to compact dimensions

- Automatic lowering of the head unit for aesthetics and additional protection against vandalism

- Touchscreen for faultless operation

- Use with classic charging plugs

- Robust housing

- Maintenance access to the head unit

- Robust against parking bumps due to patented predetermined bending point

Large CHARGING STATION

- Integrated charging cable, thus no unnecessary carrying in the vehicle

- Shelter and rain protection by solar panel

- Release of the touchscreen after verification

- Use with classic fast charging plugs or the paXos Cool-Load Megawatt

- No touching of the ground by the charging cable due to intelligent cable routing

- Increased safety for users in the event of a crash due to predetermined bending point

- Maintenance access for fast and uncomplicated inspection

- Increased ease of repair and sustainability due to easy replacement of individual modules

automated charging device

- Automated charging process for use in commercial vehicle area

- Realization of fast charging systems possible

- Contactless verification by mobile data systems (Car-2-Infrastructure)

- Vertically flexible adjustment of the height of the charging unit for commercial vehicles

- Safe placement of all essential elements in the charging station

- Increased safety in the event of a crash

- Mechanical safety against unintentional driving off (also accident)

- Safety of the commercial vehicle against swaying of the body due to loading and unloading or wind load

- Direction-independent charging of the vehicle (front right or left)

KONTAKT

INFORMATIONEN | BERATUNG | AUSKUNFT

Tel: +49 2173 200 43 30

Karl-Benz-Str. 9

40764 Langenfeld (Rhld.)

Deutschland / Germany